Understanding Diesel Engine Regeneration and the Role of Diesel Exhaust Fluid

Modern diesel engines are equipped with advanced emission control systems designed to meet stringent environmental standards. One critical component of these systems is the Diesel Particulate Filter (DPF), which captures soot and particulate matter from the exhaust gases. Over time, the DPF accumulates these particles, necessitating a process known as regeneration to maintain engine performance and compliance with emission regulations.

What Is DPF Regeneration?

DPF regeneration is the process by which accumulated soot in the diesel particulate filter is burned off to restore its efficiency. This is achieved by raising the exhaust temperature to a level sufficient to combust the soot particles. There are three primary types of regeneration:

- Passive Regeneration: Occurs automatically during normal driving conditions, typically at highway speeds, where the exhaust temperature is high enough to burn off soot.

- Active Regeneration: Initiated by the engine control unit when soot levels reach a certain threshold. Additional fuel is injected into the exhaust stream to increase temperature and facilitate soot combustion.

- Forced Regeneration: Performed manually by a technician when the DPF is heavily clogged and other regeneration methods are ineffective. This process involves running the engine at specific conditions to achieve the necessary exhaust temperatures.

The Role of Diesel Exhaust Fluid (DEF) in Emission Control

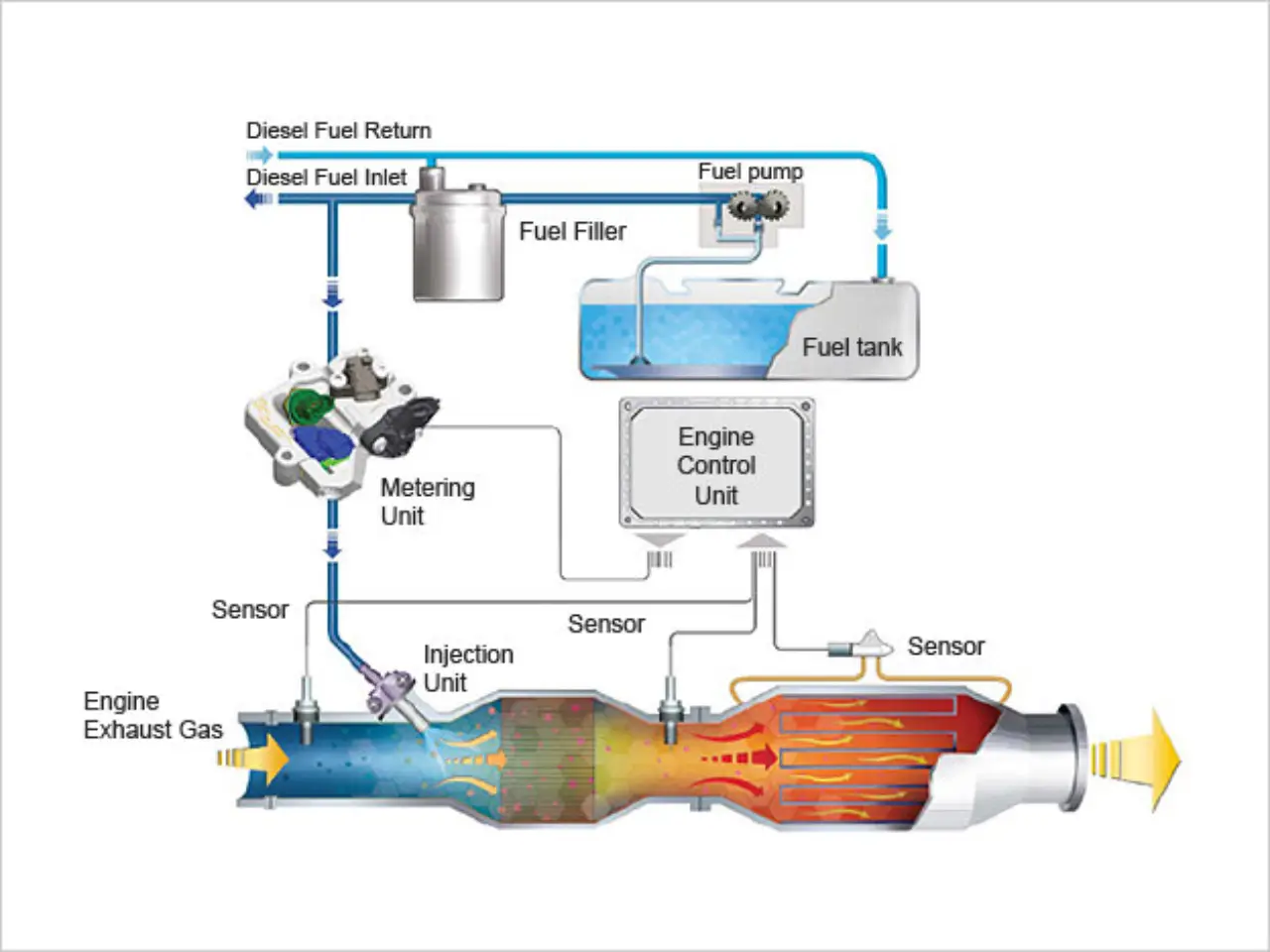

Diesel Exhaust Fluid (DEF) is a non-toxic, aqueous solution of urea and deionized water, typically composed of 32.5% urea. It is used in Selective Catalytic Reduction (SCR) systems to reduce nitrogen oxide (NOₓ) emissions from diesel engines. DEF is injected into the exhaust stream, where it reacts with NOₓ over a catalyst to produce nitrogen and water, both of which are harmless and naturally present in the atmosphere.

While DEF plays a crucial role in reducing NOₓ emissions, it does not directly participate in the DPF regeneration process. However, during active regeneration, the increased exhaust temperatures may lead to higher DEF consumption as the SCR system works to manage the elevated NOₓ levels resulting from the additional fuel injection.

Challenges and Considerations

One of the primary challenges associated with DPF regeneration is the potential for increased DEF consumption during active regeneration cycles. Since regeneration involves higher exhaust temperatures, the SCR system may require more DEF to maintain emission compliance. This can lead to more frequent DEF refills and increased operational costs.

Additionally, improper or incomplete regeneration can lead to DPF clogging, reduced engine performance, and potential damage to the exhaust system. It's essential for operators to monitor regeneration cycles and ensure that the DPF is functioning correctly to avoid these issues.

Best Practices for Managing DPF Regeneration and DEF Usage

To optimize the performance of diesel engines and manage DEF consumption effectively, consider the following best practices:

- Regular Driving at Highway Speeds: Encourage operating vehicles at highway speeds to facilitate passive regeneration, reducing the need for active or forced regeneration.

- Monitor DEF Levels: Regularly check DEF levels and top up as necessary to ensure the SCR system operates efficiently.

- Scheduled Maintenance: Adhere to manufacturer-recommended maintenance schedules for DPF cleaning and DEF system servicing to prevent buildup and ensure optimal performance.

- Educate Operators: Train vehicle operators on the importance of DPF regeneration and DEF usage to promote proactive maintenance and reduce downtime.

Conclusion

Understanding the interplay between DPF regeneration and DEF usage is crucial for maintaining the efficiency and longevity of modern diesel engines. By adopting best practices and staying informed about emission control technologies, operators can ensure compliance with environmental standards while minimizing operational costs.